Building with Straw

Building homes using straw bales has been around for many years. The first homes were built around 1920 and many of them are still in use and in perfect condition.

Straw-insulated buildings have several benefits: straw is an excellent insulation material, the walls are vapour-permeable ensuring healthy air inside the house and the materials are naturally renewable.

For a long time, the only way to build with straw was to do it the DIY way. Many self-builders have created beautiful and functional homes. The building process, however, requires a wide range of skills and even more time, making it feasible only for a small fraction of homeowners.

We were able to simplify the bulk of the necessary steps thanks to the prefabrication of panels in our factory. The elements are precision manufactured in a controlled environment allowing simple and fast on-site assembly. A typical floor is completed in a matter of hours with wet processes or waste, compared to the tedious and lengthy ways of traditional construction.

Features of EcoCocon Wall Panels

- Our panels are engineered as fully structural with a double wooden frame. They are able to support floors and roofs with no extra materials needed.

- The straw density of more than 100 kg per m3 is the guarantee of both energy efficiency and solidity.

- EcoCocon panels are certified to withstand 120+ minutes of fire when rendered.

- The assembly of panes is extremely quick even for a self-builder without a crane on site. It is possible to build the shell of the house and seal it off within days, making the rest of the construction independent of weather conditions.

- Cold bridges are eliminated for a 100% mould- and draught-free environment.

The Architecture of the Straw-Insulated House

The possibilities when building with EcoCoon are limited only by your imagination. Our system allows for any layout, size, or shape. The panels adapt to almost any design as they are made to measure down to 1-millimeter precision.

Many types of houses were built for our clients across Europe (and the first projects are being built in the United States). This is just a small preview of what's possible:

Check out the more detailed portfolio of our completed projects.

The system can be used also for multi-story construction:

Even curved walls are easily achievable:

The choice of external finishes is wide - plastering, cladding, and a combination of materials are possible. Natural interior finishes complement the EcoCocon system - wood fibre for insulation, different woods and natural linoleum for floors and ceilings, clay plaster in all colors... Tadelakt and clay techniques can be used to create beautiful and exclusive interiors.

Energy Efficiency of EcoCocon Houses

By building your house with EcoCocon panels you future-proof your project by achieving the passive house requirements.

EcoCocon provides the best conditions for the Passivhaus standard, but there are other important factors that need to be considered. These include the orientation of the house, the quality of windows and roof insulation, etc. The energy performance of a passive house always needs to be confirmed by a PHPP calculation.

Our system achieves the level of airtightness demanded by the passive house standard and yet keeps the walls completely vapour permeable (the walls allow vapour to escape to the outside).

This effectively prevents condensation in the walls which is a major problem in modern, sealed buildings.

The airtight, vapour-permeable system also creates a draught free and healthy indoor climate. Clay plaster, with its humidity regulation properties, can be applied directly to the straw panel surface.

When panels are combined with interior clay plaster and an exterior layer of 100 mm wood fibre board, the system achieves a U-value of 0.119 W/m2K (or 0.123 with 60mm wood fibre board).

The Cost of EcoCocon Houses

Every project is different, all our work is custom-made. Therefore we are unable to provide an exact figure without prior knowledge of your house design.

If you would like to get a detailed idea about the cost of the EcoCocon wall system for your house, send us your drawings by filling in the estimate request form. As a rule of thumb, our panels are comparable in terms of price with other passive and low energy construction methods.

We will offer complete kit houses for customers who prefer to buy a model home with an optimised design for a set price. Please write to us if you would like us to send you further info.

Assembly of EcoCocon House

The Foundations

The earthwork and foundations are very important stages of construction. The technical details and type of foundation depend on factors such as the ground conditions (stability and soil type) of your building plot, its topography (levels and slope) and the geographical area (if there is a risk of freezing below the foundation level).

There is no difference between foundations for a house built with EcoCocon and a conventional house. If you want to achieve the Passivhaus standard, you can use one of our ready prepared details without thermal bridges. Depending on the overall design of the house, strip or raft foundations, a concrete slab or piles can be used.

It is recommended to work with a local architect or engineer who will give you professional advice. The finished surface needs to be level and dry to ensure the panels can be installed according to specifications.

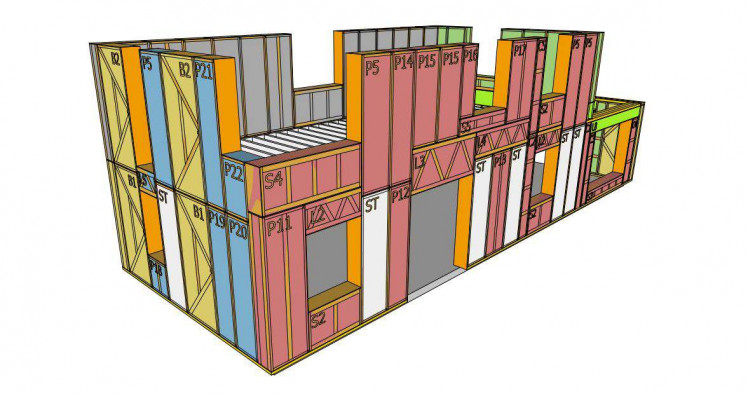

Delivery and Assembly of Wall Panels

The delivery of EcoCocon panels takes place when your foundations are ready. Panels arrive on a lorry and can be unloaded by hand or with a forklift/crane. Panels can be stored onsite if necessary, but it is important to cover them properly to avoid any contact with water.

A base plate is then formed. Its purpose is to create a level of insulation from the concrete below.

Panels are placed onto the base plate and fixed in place. The assembly follows the panel project. Each panel is clearly indicated by its number and a color code.

Only basic tools are needed - impact screwdriver, a hammer, saw, and a few other carpentry tools. All the necessary hardware such as screws is included with the panels.

Making the House Airtight

Erected walls are then covered with an airtight protective membrane. The membrane is stapled or screwed through plywood strips.

Load-bearing beams, ceiling and roof are installed next, according to the design of your house. At this stage, the house is protected from water damage and finishing works can start.

Roof

After all the connections are taped and the membrane is secured by the plywood strips, the top ring beams are installed and fixed by screws. They will support the roof structure.

Ceilings

Floor joists can be installed directly to the wall panels through a vertical ring beam. The ring beam is fixed directly to the vertical posts of the EcoCocon panels. Joists can be placed with a spacing regardless of the position of the wall posts.

Installation of Exterior Layers

Wood fibre boards are installed on the exterior surface. The plywood strips compensate for straw sticking out from the wooden frame providing a level surface.

The exterior finish options include several types of plaster and cladding systems.